It turns out there’s a science to making sure every smoke is just right—it’s called draw testing.

You might think it’s all about tradition and skilled hands rolling tobacco leaves together; well, you’re not wrong. But there’s also an arsenal of tech and precision behind ensuring that every single cigar offers up the ideal resistance when you take a drag.

I’ve seen firsthand how much effort goes into crafting these beauties—and trust me, once I pull back the curtain on what makes Perdomo Cigars stand out in their relentless pursuit of quality through draw testing… You’ll see why those perfect draws in every stick are no accident. They’re a testament to their commitment to excellence.

Table Of Contents:

- The Science of Draw Testing in Premium Cigars

- The Artisans Behind the Draw Testing Stations

- The Perdomo Commitment to Quality Through Draw Testing

- How Draw Testing Enhances Your Smoking Experience

- Perdomo’s Range of Testable Cigar Sizes

- Innovations in Draw Testing Technology

- Ensuring Consistency in Every Puff

- A Closer Look at Perdomo’s Draw Testing Equipment

- FAQs in Relation to Draw Testing Premium Cigars

- Conclusion

The Science of Draw Testing in Premium Cigars

Imagine lighting up a premium cigar only to find the draw too tight or loose, like sipping a milkshake through a coffee stirrer or trying to catch wind with a fishing net. That’s where draw testing comes into play, and it’s not just puffing and hoping for the best—it’s pure science.

Understanding Drop Pressure Machines

A drop pressure machine is like an unsung hero that can make or break your smoking experience. This gadget takes each cigar on a test run without lighting up—think of it as giving cigars a treadmill workout before they hit the shelves. It measures how much air passes through by applying precise pressure, so you don’t have to deal with surprises once you’re ready to kick back and relax.

If we get technical—and why wouldn’t we?—it’s all about numbers: three pounds per square inch (psi) might be perfect for one size but could spell disaster for another. And these machines are meticulously calibrated because nobody wants their relaxation time turned into work.

The Role of Standardization in Draw Testing

Consistency is king when ensuring every puff delivers satisfaction. Jigs act as templates during testing—they’re essentially blueprints ensuring every cigar gets equal treatment under scrutiny; think cookie cutters but way more sophisticated.

We’ve got our trusty jigs set at standardized dimensions so that no matter which stogie you choose from Doc James Cigars’ lineup, five out six times (and those are good odds), your smoke will be smooth sailing—or should I say smoking?

Tailoring Pressure for Different Cigar Sizes

Different strokes for different folks—and different pressures for different cigars. A Churchill demands its own unique touch compared to, say, a Robusto; seven varying levels must be spot-on to ensure your taste buds aren’t left hanging dry—or drowning in smoke.

Crafting that ideal airflow isn’t guesswork; it requires precision akin to tuning an instrument until the sound resonates perfectly clear—a symphony conducted by expert hands backed by years of tradition woven into modern technology.

Key Takeaway:

Draw testing is the unsung hero of your smoking experience, ensuring each puff is just right by measuring airflow with scientific precision. No more surprises—just sit back and enjoy a perfectly calibrated smoke every time.

The Artisans Behind the Draw Testing Stations

From Bunchers to Quality Controllers

The unsung heroes of the cigar world aren’t just those who expertly roll your favorite sticks—they’re also the vigilant quality controllers at draw testing stations. Picture this: a maestro of tobacco, once a master buncher, now ensures that every puff you take is nothing short of perfection. These artisans have traded their rolling tables for tech-savvy machines that measure air flow through each cigar—a transition as significant as Beethoven swapping his piano for a conductor’s baton.

But why does this matter? Because these former rollers bring with them years—often decades—of experience in crafting cigars by hand. They know what feels right and what doesn’t; it’s an art form passed down like precious family recipes but spiced up with modern precision.

This switch from hands-on creation to quality control isn’t just about maintaining standards—it’s about elevating them. When someone who can tell good tobacco simply by its scent gets their hands on state-of-the-art machinery, magic happens. Each tester applies their unique touch, fine-tuning pressure adjustments so that whether you’re lighting up a robusto or Churchill, the draw is always spot on.

The Perdomo Commitment to Quality Through Draw Testing

Over a Decade of Rigorous Standards

If you think about it, ensuring the perfect draw in a cigar is like fine-tuning an instrument before a concert. It’s not just about hitting the right notes; it’s making sure every puff sings with quality. That’s what Perdomo Cigars has been doing for over 15 years—meticulously testing each and every cigar to guarantee that premium experience.

Imagine standing in line at your favorite coffee shop day after day and always getting that first flawless sip of java—that’s what consistent draw testing offers to aficionados. It turns out, perfection isn’t stumbled upon by chance; it’s crafted through relentless dedication.

This is why one might say that Nick Perdomo—the maestro behind this symphony—is not only producing cigars but also orchestrating an unparalleled smoking experience time after time. With such commitment woven into their process, they ensure no consumer ever faces the disappointment of a poorly constructed stogie—a testament truly befitting their name on the marquee of excellence.

How Draw Testing Enhances Your Smoking Experience

Imagine lighting up a cigar and finding the draw too tight or too loose, turning what should be an indulgent experience into a frustrating tug-of-war with your stogie. That’s where draw testing comes in as the unsung hero of your smoking pleasure. Perdomo Cigars doesn’t play games when it comes to ensuring that each puff is nothing short of perfection—they’ve been at this for over 15 years, treating every single cigar like royalty before it makes its grand entrance.

A meticulous draw test can mean the difference between savoring a well-crafted symphony of flavors and wrestling with an uncooperative lump of tobacco leaves. The craft behind premium cigars lies not just in their composition but also in their ability to deliver consistent airflow, which directly impacts flavor release and smoke density. It’s akin to tuning a fine instrument; without proper calibration, you’ll never hear the sweet music it was meant to play.

This attention to detail ensures that whether you’re unwinding after a long day or celebrating life’s milestones, each drag from your cigar will be smooth sailing—no hiccups allowed. With Perdomo’s steadfast commitment to quality control, rest assured that sophistication is packed tightly within every inch waiting for you—the aficionado—to ignite.

Perdomo’s Range of Testable Cigar Sizes

Imagine trying on shoes that fit just right, no matter the style or size. That’s Perdomo when it comes to draw testing cigars across a spectrum of sizes. They’ve got their hands in every pot, from robustos to churchills, ensuring each puff is like walking on air.

Their versatility shines as they tweak pressures for different cigar diameters and lengths. It’s not one-size-fits-all; these folks adjust with precision so your Churchill isn’t gasping for breath while your Corona isn’t blowing smoke rings without you.

Now think about those jeans that look great but can’t handle a squat – annoying, right? Perdomo dodges this by test-driving every single stick. This means before any cigar gets the green light, it has already gone through an obstacle course designed to make sure your smoking experience won’t have you doing mental gymnastics trying to get a decent drag.

Tailoring Pressure for Different Cigar Sizes

Sure, pressure matters in relationships and tires—but let’s talk cigars. You don’t want too much fight or flop when drawing on your stogie; balance is key here. The magic number lies somewhere between ‘just enough’ and ‘not too much,’ kind of like finding the volume sweet spot during a road trip jam session.

So whether it’s taking care of giants like Presidentes or tending to petites without losing quality—it’s all part of how Perdomo ensures consistency across its broad range. They’re known for meticulously regulating draw resistance, guaranteeing satisfaction from first spark till last ash falls softly into the tray—every time.

Innovations in Draw Testing Technology

When it comes to ensuring a premium cigar delivers that smooth, satisfying draw, technology is the unsung hero. Remember when you had to guess whether your next puff would be bliss or a bust? Those days are as gone as dial-up internet, thanks to innovations in draw testing.

The evolution of this tech has been like upgrading from an old flip phone to the latest smartphone—it’s all about precision and reliability. Cigar aficionados know nothing ruins a good smoke like having to huff and puff harder than the Big Bad Wolf trying to take down those three little pigs’ houses. That’s where modern machinery steps up, doing more than just rolling dice on quality; they’re measuring every breath of resistance with science-fiction-like accuracy.

Imagine if your car only started 7 out of 10 times—you wouldn’t stand for it. Well, neither do top-notch cigar producers. They’re using advanced machines that give them stats so consistent you’d think they were made by robots programmed with OCD. The leap forward here isn’t just impressive; it’s essential because who wants their chill time interrupted by subpar craftsmanship? So hats off (and lighters up) for the high-tech guardians making sure our smokes don’t go up in…well, smoke.

Ensuring Consistency in Every Puff

If you’ve ever lit up a premium cigar, you know that an even draw is the secret handshake to nirvana. But what does it take to make sure each puff doesn’t play tug-of-war with your cheeks? It’s all about consistency – and that’s where Perdomo Cigars’ obsession with detail shines.

Their meticulous process of draw testing ensures no smoker is left pulling harder than a lawn mower starter. Picture this: Each cigar goes through its paces like an athlete at the NFL Combine—measured, tested, and only passing muster if every breath in feels as effortless as breathing out on a lazy Sunday.

This isn’t just rolling dice hoping for lucky sevens; we’re talking about drop pressure machines humming along like NASA techs at launch control ensuring each piece of handcrafted tobacco gold has just the right amount of give. That means whether it’s your first dance or thousandth rodeo with a Perdomo stick, rest assured knowing there won’t be any unwanted surprises from start to nub.

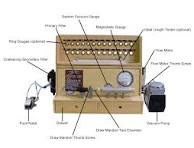

A Closer Look at Perdomo’s Draw Testing Equipment

The Precision of Pedal-Controlled Pressure Application

Imagine a pianist, where each press of the pedal can evoke an entirely different sound. That’s how Perdomo Cigars approaches draw testing: with precision that could rival a concert hall performance. Their equipment includes pedal-controlled machines that allow operators to apply just the right amount of pressure when testing each cigar’s draw.

This isn’t about haphazardly squeezing cigars to see what happens; it’s more like conducting surgery—except here, the patient is your soon-to-be favorite smoke. The operators use their foot pedals with finesse and experience, knowing exactly how much pressure will ensure you get a smooth pull from every puff.

But why does this matter? Well, think about sipping on your preferred drink through a straw. Not enough oomph and you’re struggling for breath; too much power and it’s like gulping from a fireman’s hose. Now imagine that in cigar form – yeah, not ideal. So by fine-tuning this aspect alone, Perdomo makes sure every single one of their premium cigars hits that sweet spot for smokers.

FAQs in Relation to Draw Testing Premium Cigars

Why am I not getting a good draw on my cigar?

Poor draw could be from a tightly packed cigar or an obstructed airflow. Check for hard spots.

How do you get a good draw from a cigar?

To improve the draw, gently massage any tight areas or use a tool to carefully loosen up the fill.

What is a cigar draw enhancer?

A cigar draw enhancer is a tool that creates channels in the filler to ease airflow and fix tight draws.

What does ‘draw’ mean in cigars?

In cigars, ‘draw’ refers to how air moves through it when puffed; crucial for flavor delivery and smoke production.

Conclusion

Draw testing premium cigars is an art, honed by skilled artisans. It’s the hidden champion behind your flawless smoke.

This meticulous process uses drop pressure machines to hit that sweet spot of resistance. From ensuring consistent quality to accommodating various cigar sizes, it’s about precision at every puff.

Perdomo Cigars has been nailing this for over a decade because they get it—quality matters. They’ve invested in people and tech to keep their promise of excellence alive in each cigar you light up.

So, as you enjoy a Perdomo cigar, think about the craftsmanship behind it. This isn’t just any smoke—it’s a legacy of quality that comes from years of hard work and an unwavering commitment to excellence in every puff.

Picture this: you’re kicking back in your favorite chair, the day’s work done, with a premium cigar between your fingers. That first draw is supposed to be smooth, rich—blissful even. But sometimes it’s not. It can be too tight or too loose and that perfect moment becomes a battle for each puff.

It turns out there’s a science to making sure every smoke is just right—it’s called draw testing.

You might think it’s all about tradition and skilled hands rolling tobacco leaves together; well, you’re not wrong. But there’s also an arsenal of tech and precision behind ensuring that every single cigar offers up the ideal resistance when you take a drag.

I’ve seen firsthand how much effort goes into crafting these beauties—and trust me, once I pull back the curtain on what makes Perdomo Cigars stand out in their relentless pursuit of quality through draw testing… You’ll see why those perfect draws in every stick are no accident. They’re a testament to their commitment to excellence.

Table Of Contents:

- The Science of Draw Testing in Premium Cigars

- The Artisans Behind the Draw Testing Stations

- The Perdomo Commitment to Quality Through Draw Testing

- How Draw Testing Enhances Your Smoking Experience

- Perdomo’s Range of Testable Cigar Sizes

- Innovations in Draw Testing Technology

- Ensuring Consistency in Every Puff

- A Closer Look at Perdomo’s Draw Testing Equipment

- FAQs in Relation to Draw Testing Premium Cigars

- Conclusion

The Science of Draw Testing in Premium Cigars

Imagine lighting up a premium cigar only to find the draw too tight or loose, like sipping a milkshake through a coffee stirrer or trying to catch wind with a fishing net. That’s where draw testing comes into play, and it’s not just puffing and hoping for the best—it’s pure science.

Understanding Drop Pressure Machines

A drop pressure machine is like an unsung hero that can make or break your smoking experience. This gadget takes each cigar on a test run without lighting up—think of it as giving cigars a treadmill workout before they hit the shelves. It measures how much air passes through by applying precise pressure, so you don’t have to deal with surprises once you’re ready to kick back and relax.

If we get technical—and why wouldn’t we?—it’s all about numbers: three pounds per square inch (psi) might be perfect for one size but could spell disaster for another. And these machines are meticulously calibrated because nobody wants their relaxation time turned into work.

The Role of Standardization in Draw Testing

Consistency is king when ensuring every puff delivers satisfaction. Jigs act as templates during testing—they’re essentially blueprints ensuring every cigar gets equal treatment under scrutiny; think cookie cutters but way more sophisticated.

We’ve got our trusty jigs set at standardized dimensions so that no matter which stogie you choose from Doc James Cigars’ lineup, five out six times (and those are good odds), your smoke will be smooth sailing—or should I say smoking?

Tailoring Pressure for Different Cigar Sizes

Different strokes for different folks—and different pressures for different cigars. A Churchill demands its own unique touch compared to, say, a Robusto; seven varying levels must be spot-on to ensure your taste buds aren’t left hanging dry—or drowning in smoke.

Crafting that ideal airflow isn’t guesswork; it requires precision akin to tuning an instrument until the sound resonates perfectly clear—a symphony conducted by expert hands backed by years of tradition woven into modern technology.

Key Takeaway:

Draw testing is the unsung hero of your smoking experience, ensuring each puff is just right by measuring airflow with scientific precision. No more surprises—just sit back and enjoy a perfectly calibrated smoke every time.

The Artisans Behind the Draw Testing Stations

From Bunchers to Quality Controllers

The unsung heroes of the cigar world aren’t just those who expertly roll your favorite sticks—they’re also the vigilant quality controllers at draw testing stations. Picture this: a maestro of tobacco, once a master buncher, now ensures that every puff you take is nothing short of perfection. These artisans have traded their rolling tables for tech-savvy machines that measure air flow through each cigar—a transition as significant as Beethoven swapping his piano for a conductor’s baton.

But why does this matter? Because these former rollers bring with them years—often decades—of experience in crafting cigars by hand. They know what feels right and what doesn’t; it’s an art form passed down like precious family recipes but spiced up with modern precision.

This switch from hands-on creation to quality control isn’t just about maintaining standards—it’s about elevating them. When someone who can tell good tobacco simply by its scent gets their hands on state-of-the-art machinery, magic happens. Each tester applies their unique touch, fine-tuning pressure adjustments so that whether you’re lighting up a robusto or Churchill, the draw is always spot on.

The Perdomo Commitment to Quality Through Draw Testing

Over a Decade of Rigorous Standards

If you think about it, ensuring the perfect draw in a cigar is like fine-tuning an instrument before a concert. It’s not just about hitting the right notes; it’s making sure every puff sings with quality. That’s what Perdomo Cigars has been doing for over 15 years—meticulously testing each and every cigar to guarantee that premium experience.

Imagine standing in line at your favorite coffee shop day after day and always getting that first flawless sip of java—that’s what consistent draw testing offers to aficionados. It turns out, perfection isn’t stumbled upon by chance; it’s crafted through relentless dedication.

This is why one might say that Nick Perdomo—the maestro behind this symphony—is not only producing cigars but also orchestrating an unparalleled smoking experience time after time. With such commitment woven into their process, they ensure no consumer ever faces the disappointment of a poorly constructed stogie—a testament truly befitting their name on the marquee of excellence.

How Draw Testing Enhances Your Smoking Experience

Imagine lighting up a cigar and finding the draw too tight or too loose, turning what should be an indulgent experience into a frustrating tug-of-war with your stogie. That’s where draw testing comes in as the unsung hero of your smoking pleasure. Perdomo Cigars doesn’t play games when it comes to ensuring that each puff is nothing short of perfection—they’ve been at this for over 15 years, treating every single cigar like royalty before it makes its grand entrance.

A meticulous draw test can mean the difference between savoring a well-crafted symphony of flavors and wrestling with an uncooperative lump of tobacco leaves. The craft behind premium cigars lies not just in their composition but also in their ability to deliver consistent airflow, which directly impacts flavor release and smoke density. It’s akin to tuning a fine instrument; without proper calibration, you’ll never hear the sweet music it was meant to play.

This attention to detail ensures that whether you’re unwinding after a long day or celebrating life’s milestones, each drag from your cigar will be smooth sailing—no hiccups allowed. With Perdomo’s steadfast commitment to quality control, rest assured that sophistication is packed tightly within every inch waiting for you—the aficionado—to ignite.

Perdomo’s Range of Testable Cigar Sizes

Imagine trying on shoes that fit just right, no matter the style or size. That’s Perdomo when it comes to draw testing cigars across a spectrum of sizes. They’ve got their hands in every pot, from robustos to churchills, ensuring each puff is like walking on air.

Their versatility shines as they tweak pressures for different cigar diameters and lengths. It’s not one-size-fits-all; these folks adjust with precision so your Churchill isn’t gasping for breath while your Corona isn’t blowing smoke rings without you.

Now think about those jeans that look great but can’t handle a squat – annoying, right? Perdomo dodges this by test-driving every single stick. This means before any cigar gets the green light, it has already gone through an obstacle course designed to make sure your smoking experience won’t have you doing mental gymnastics trying to get a decent drag.

Tailoring Pressure for Different Cigar Sizes

Sure, pressure matters in relationships and tires—but let’s talk cigars. You don’t want too much fight or flop when drawing on your stogie; balance is key here. The magic number lies somewhere between ‘just enough’ and ‘not too much,’ kind of like finding the volume sweet spot during a road trip jam session.

So whether it’s taking care of giants like Presidentes or tending to petites without losing quality—it’s all part of how Perdomo ensures consistency across its broad range. They’re known for meticulously regulating draw resistance, guaranteeing satisfaction from first spark till last ash falls softly into the tray—every time.

Innovations in Draw Testing Technology

When it comes to ensuring a premium cigar delivers that smooth, satisfying draw, technology is the unsung hero. Remember when you had to guess whether your next puff would be bliss or a bust? Those days are as gone as dial-up internet, thanks to innovations in draw testing.

The evolution of this tech has been like upgrading from an old flip phone to the latest smartphone—it’s all about precision and reliability. Cigar aficionados know nothing ruins a good smoke like having to huff and puff harder than the Big Bad Wolf trying to take down those three little pigs’ houses. That’s where modern machinery steps up, doing more than just rolling dice on quality; they’re measuring every breath of resistance with science-fiction-like accuracy.

Imagine if your car only started 7 out of 10 times—you wouldn’t stand for it. Well, neither do top-notch cigar producers. They’re using advanced machines that give them stats so consistent you’d think they were made by robots programmed with OCD. The leap forward here isn’t just impressive; it’s essential because who wants their chill time interrupted by subpar craftsmanship? So hats off (and lighters up) for the high-tech guardians making sure our smokes don’t go up in…well, smoke.

Ensuring Consistency in Every Puff

If you’ve ever lit up a premium cigar, you know that an even draw is the secret handshake to nirvana. But what does it take to make sure each puff doesn’t play tug-of-war with your cheeks? It’s all about consistency – and that’s where Perdomo Cigars’ obsession with detail shines.

Their meticulous process of draw testing ensures no smoker is left pulling harder than a lawn mower starter. Picture this: Each cigar goes through its paces like an athlete at the NFL Combine—measured, tested, and only passing muster if every breath in feels as effortless as breathing out on a lazy Sunday.

This isn’t just rolling dice hoping for lucky sevens; we’re talking about drop pressure machines humming along like NASA techs at launch control ensuring each piece of handcrafted tobacco gold has just the right amount of give. That means whether it’s your first dance or thousandth rodeo with a Perdomo stick, rest assured knowing there won’t be any unwanted surprises from start to nub.

A Closer Look at Perdomo’s Draw Testing Equipment

The Precision of Pedal-Controlled Pressure Application

Imagine a pianist, where each press of the pedal can evoke an entirely different sound. That’s how Perdomo Cigars approaches draw testing: with precision that could rival a concert hall performance. Their equipment includes pedal-controlled machines that allow operators to apply just the right amount of pressure when testing each cigar’s draw.

This isn’t about haphazardly squeezing cigars to see what happens; it’s more like conducting surgery—except here, the patient is your soon-to-be favorite smoke. The operators use their foot pedals with finesse and experience, knowing exactly how much pressure will ensure you get a smooth pull from every puff.

But why does this matter? Well, think about sipping on your preferred drink through a straw. Not enough oomph and you’re struggling for breath; too much power and it’s like gulping from a fireman’s hose. Now imagine that in cigar form – yeah, not ideal. So by fine-tuning this aspect alone, Perdomo makes sure every single one of their premium cigars hits that sweet spot for smokers.

FAQs in Relation to Draw Testing Premium Cigars

Why am I not getting a good draw on my cigar?

Poor draw could be from a tightly packed cigar or an obstructed airflow. Check for hard spots.

How do you get a good draw from a cigar?

To improve the draw, gently massage any tight areas or use a tool to carefully loosen up the fill.

What is a cigar draw enhancer?

A cigar draw enhancer is a tool that creates channels in the filler to ease airflow and fix tight draws.

What does ‘draw’ mean in cigars?

In cigars, ‘draw’ refers to how air moves through it when puffed; crucial for flavor delivery and smoke production.

Conclusion

Draw testing premium cigars is an art, honed by skilled artisans. It’s the hidden champion behind your flawless smoke.

This meticulous process uses drop pressure machines to hit that sweet spot of resistance. From ensuring consistent quality to accommodating various cigar sizes, it’s about precision at every puff.

Perdomo Cigars has been nailing this for over a decade because they get it—quality matters. They’ve invested in people and tech to keep their promise of excellence alive in each cigar you light up.

So, as you enjoy a Perdomo cigar, think about the craftsmanship behind it. This isn’t just any smoke—it’s a legacy of quality that comes from years of hard work and an unwavering commitment to excellence in every puff.